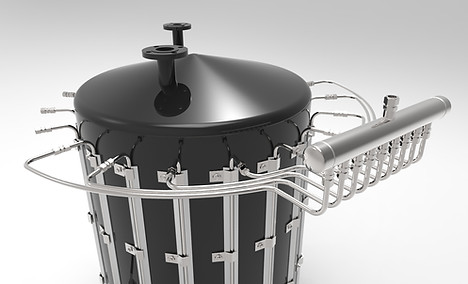

SUB-HEADERS for Tank Heating

QMax Sub-Headers maximize the efficiency of systems that use steam or hot oil to heat a particular process. By using Sub-Headers, it allows the operator to pinpoint the breakout area for multiple circuits. In the case of steam, it eliminates the need to route multiple lines from the boiler or steam header. Instead, a single supply line can run directly from the boiler to the Sub-Header, which splits into multiple tubing circuits for heating with QMax FTS (Fluid Tracing System). At the end of the QMax FTS run, another Sub-Header can be used to collect the circuits and trap condensate with a single steam trap. This lowers the amount of pre-insulated tubing and manifolds required on the supply side, while also reducing the number of condensate traps needed at the return side.

ADVANTAGES:

-

Allows operator to pinpoint breakout area for multiple circuits

-

Eliminates the need to route multiple lines from the boiler or steam header

-

A single supply can run directly from the boiler to the sub-header

-

Can be used to trap condensate from multiple circuits into a single trap

QMax Sub-Headers are custom fabricated to your needs, and made from either carbon or stainless steel. With a variety of options for welded fittings such as Swagelok tube fittings, flanges, pipe ends or threaded connections, QMax will deliver the Sub-Header that works with your system, just the way you want it to.